Issue

The production line was being automated up to the packing stage. However, frequent false detections by the inspection system required workers to provide periodic manual assistance.

They were seeking a highly accurate inspection system with minimal false detections.

Solution

By introducing an X-ray inspection system equipped with AI inspection options for detecting seal defects, false detections were reduced and stable detection and rejection of seal defects was achieved.

Background:Seal defects on trays not only impair the product’s appearance but may also significantly reduce its shelf life

Depending on the location of the seal defect, shelf life can be compromised, posing a quality management challenge.

In the past, it was difficult to detect products with fragments of ham or oil trapped in the seal area. Existing inspection systems had frequent false detections, making it unclear how many defective products had reached the market.

Reason of installation:False detections by the existing inspection system were preventing full automation of the production line.

Over the past few years, the customer had been upgrading its facilities to achieve automation up to the packing stage. However, the existing inspection system frequently produced false detections (e.g., identifying good products as defective), requiring periodic manual intervention by operators. To further advance automation, the introduction of a highly accurate inspection system was essential.

How it works:False detections were reduced and stable inspection was achieved through the AI inspection option.

By introducing the seal defect X-ray inspection system with AI inspection, the inspection became more stable and false detections decreased.

The AI learns and accumulates data, allowing the system to detect only seal defects while excluding false detections caused by factors such as tray warping. Manual assistance is no longer required. In addition, the frequency of tray seal defects has been quantified at less than 0.3%, providing clear data to support future improvements in productivity.

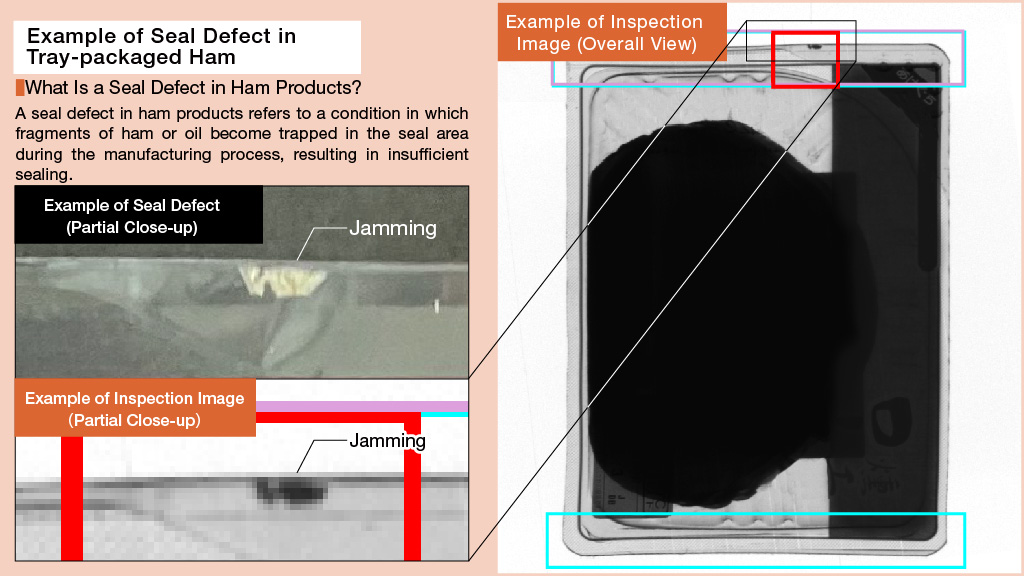

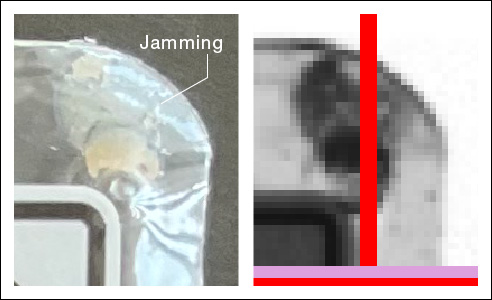

- ▲The seal defect area is small, as shown in the image, and when oil is trapped, the defect becomes even harder to detect.

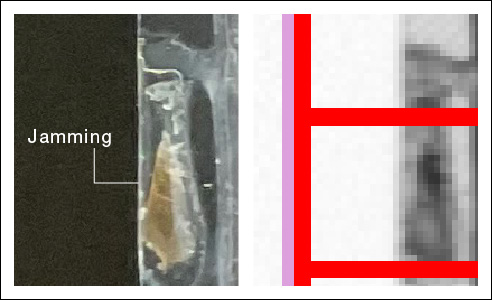

- ▲Example of Seal Defect Caused by Ham Fragments.

- ▲Example of Seal Defect Caused by Oil Inclusion.

- ▲Illustration for reference only.

- ▲AI builds the optimal classification model.

*Some cases may contain special options as necessary.

*Contents are subject to change without prior notice.

Posted2025/10/30

Updated2025/10/30

Model:

X-ray Seal Inspection System

SXS2-2154HC1D / SXS2-3474HC1D

Both Foreign body & Seal fault are detected with one system. After packaged even with aluminum or other material, the X-ray and optical system see inside and find “Jamming (Seal fault)”, “Foreign object”, “Relative mass”, “Shape”, “Numbers”, “Length”, etc.